Description

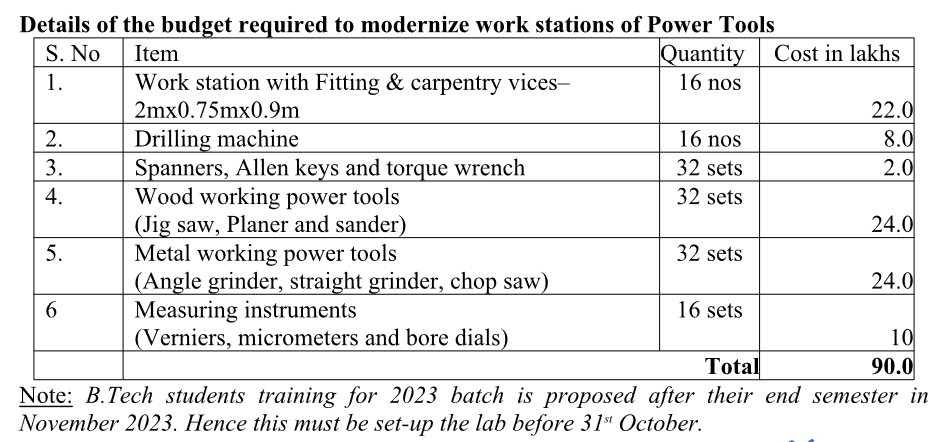

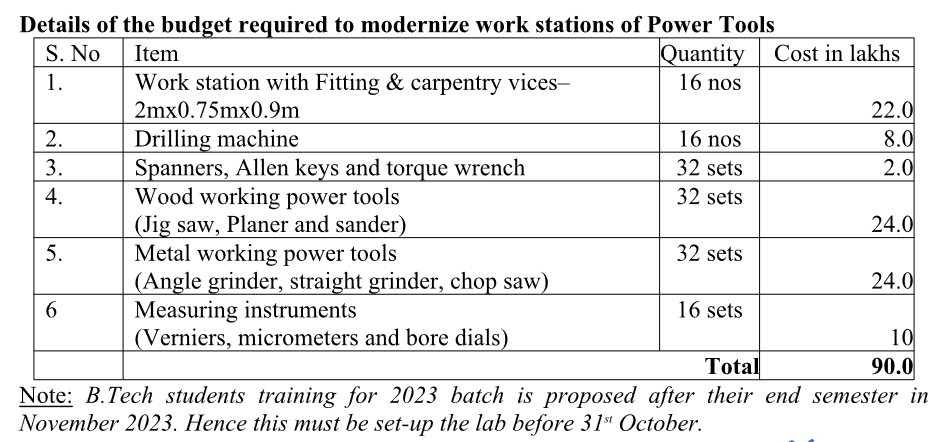

Central Skill Training & Fabrication - CSTF facility (formerly known as Central Workshop) offers workshop practical courses to all the first year B. Tech and Dual Degree students. Fitting and carpentry shops train the students to use wood working and metal working tools. In 1960, when the work shop was started, the students were trained to use hand tools for Metal and wood working process in Fitting and carpentry shops. The work benches were designed to use hand tools and there was no need to have electrical connections in the work benches. Figures 1 & 2 show the Fitting shop tables for metal working. Figures 3 & 4 show the Carpentry shop tables for wood working.

The development of technology using electrical and pneumatic power had happened in past few decades. In IIT Madras, training of students using hand held electrical power tools started in the year 2010. All the B. Tech students of IITM are trained to operate hand held Electric power tools such as Jig saw, Chop saw, Circular saw, Planer , sander and angle grinders for wood and metal working. Existing work tables made in 1960s are used with extension boxes for power tools operation. Students are instructed to use the power tools very safely using temporary electrical connections in work tables. Also the existing tables made in 1960s got damaged due to the use of last 6 decades by 30000-40000 students of IIT Madras. Due to continuous usage of these tables and vices is not in proper condition. So it is proposed to move to the next generation power tool Work station providing latest electric and pneumatic power tools operations to the students of IIT Madras.

A prototype modern power tool workstation unit developed by us (see Figure 5 is equipped with Electrical & Pneumatic connections, and tools such as allen key sets riveting guns and torque wrenches set of plier’s screw drivers and power tools like angle grinding, die grinding, Jig saw, planner& basic tools etc.

The learning objectives are (1) to train the students to use hand held tools and hand-held portable power tools for wood and metal working processes, (2) disassembly and assembly of a product using power tools. Students will also understand the torque applied to tighten various fasteners during assembly process. A drilling set is also provided in the work station for drilling operations in the work pieces; there is no need to wait in a queue to use drilling machines away from the working area.

The work station unit in Figure.5 also comes with inbuilt power card and equipped with one drilling, 2 metal and 2 wood working bench vices which minimize the time saving and roaming the student here and there.

It is proposed to make 16 such work station units, each having 2 separate work stations/table to handle total of 32 students in a batch which is the current requirement.

Next Generation Powertool Workstation at IITM

- No.of Donors : 1